Helping Convenience Food Manufacturers Meet Ever-Changing Challenges

UK ready meal manufacturers are facing a perfect storm of evolving consumer appetites, sustainability imperatives, and rigorous retail demands. In this landscape, the packaging line is where a good product becomes a great proposition – and where specialist engineering from companies like Flexi-Pak can make a significant difference.

Fit for the Chiller: Packaging Trends and Essential Considerations

Whether it's meal pots, trays, or pouches, manufacturers planning a new packaging line for convenience foods or ready meals have several priorities to juggle. First is flexibility: with line downtime costly and supermarket orders increasingly variable, engineers require equipment capable of rapid changeovers and instant recipe recall. Flexi-Pak, a UK packaging machinery manufacturer based in Gainsborough, was established to develop precisely this type of end-of-line packaging machinery. The company offers a wide range of machinery designed with high modularity and user-friendly interfaces for operators who need to adjust runs on the fly.

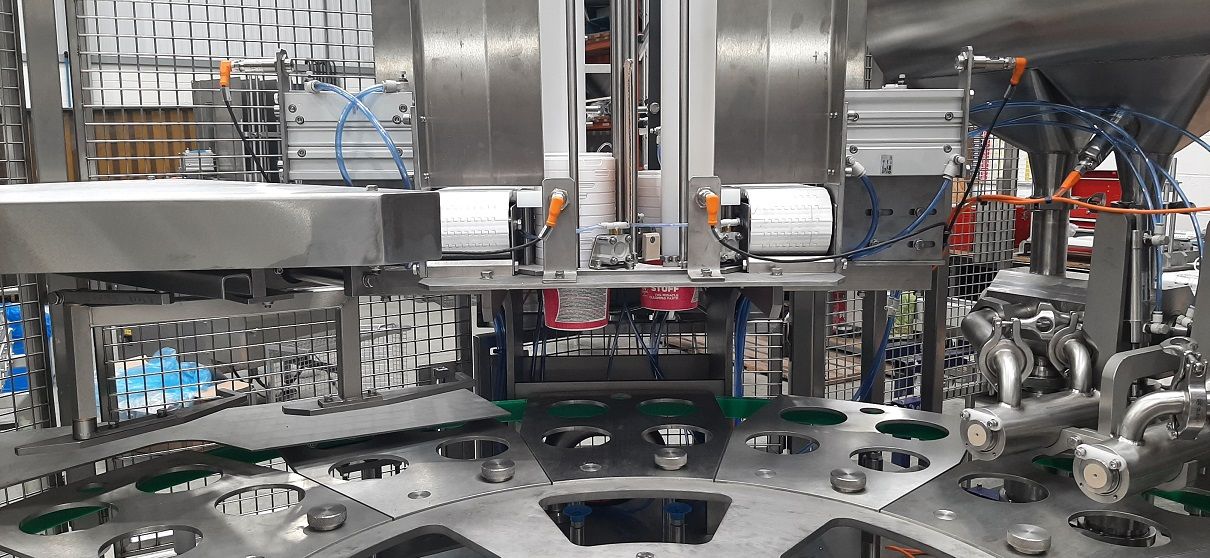

Hygiene is also paramount. Machinery built primarily from stainless steel and food-grade plastics – as is the case with all Flexi-Pak's equipment – has become the norm, reflecting not just industry regulations for high-care environments but also mounting consumer concerns about food safety.

Retailers and meal brands are also laser-focused on presentation and shelf life. Modified Atmosphere Packaging (MAP), vacuum-seal solutions, and skin packs are being used to lock in freshness and maximise shelf life. The latest solutions, like vacuum-packed foil trays, seek to balance shelf appeal with practicality, allowing meals to be cooked directly in the packaging and displayed vertically – a common feature in the chilled aisle.

Engineering in Practice: The Flexi-Pak Approach

Flexi-Pak has developed an extensive range of machinery which can be customised and modified to suit each application and installation. When it comes to convenience foods and ready meals, Flexi-Pak offers:

- Rotary and linear pot filling machines – capable of handling everything from creamy risottos to hearty stews

- Tray and skillet de-nesters and lidders for rapid throughput

- Deposit systems for both liquid and dry ingredients

- Conveyors and end-of-line systems, including robotic case packing and tray loading

- Custom-built conveyors, carton erectors, and sealers to maximise throughput and protect delicate products

As well as in-house engineering, design, development and installation, the Flexi-Pak's directors' vision when establishing the company was to provide exceptional after-sales support to its customers. By carrying large volumes of spare parts and offering rapid response times to support calls, Flexi-Pak now has a reputation not only for delivering bespoke engineering solutions that offer incredible efficiency but also for a level of after-sales support uncommon in the food industry.

As the ready meals category continues to evolve, with new trends emerging in taste, nutrition, and convenient formats, the pressure on engineering departments to develop efficient and reliable packaging lines will only grow. The team at Flexi-Pak believe that those who invest in future-proof, hygienic, and easily upgradable systems will be best placed to meet these challenges.

If you're considering investing in a new packing line for ready meals or convenience foods and would like some help and advice please don't hesitate to email us or call 01427 612869.