Helping Ice Cream Manufacturers Pack The Perfect Scoop

Ice cream packaging sits at the crossroads of product quality, operational efficiency, and brand presentation. For manufacturers, the challenge is not only to protect texture and taste but also to deliver fast changeovers, hygienic cleaning, and eye-catching branding.

Flexi‑Pak offers a range of UK-built packaging systems engineered for frozen desserts, combining precise filling, versatile depositing, and intelligent end‑of‑line solutions to keep lines running smoothly from batch to box.

Designed and manufactured in Gainsborough, Lincolnshire, our machinery uses bespoke designs for ice cream manufacturers, to help them meet their product specifications and throughputs.

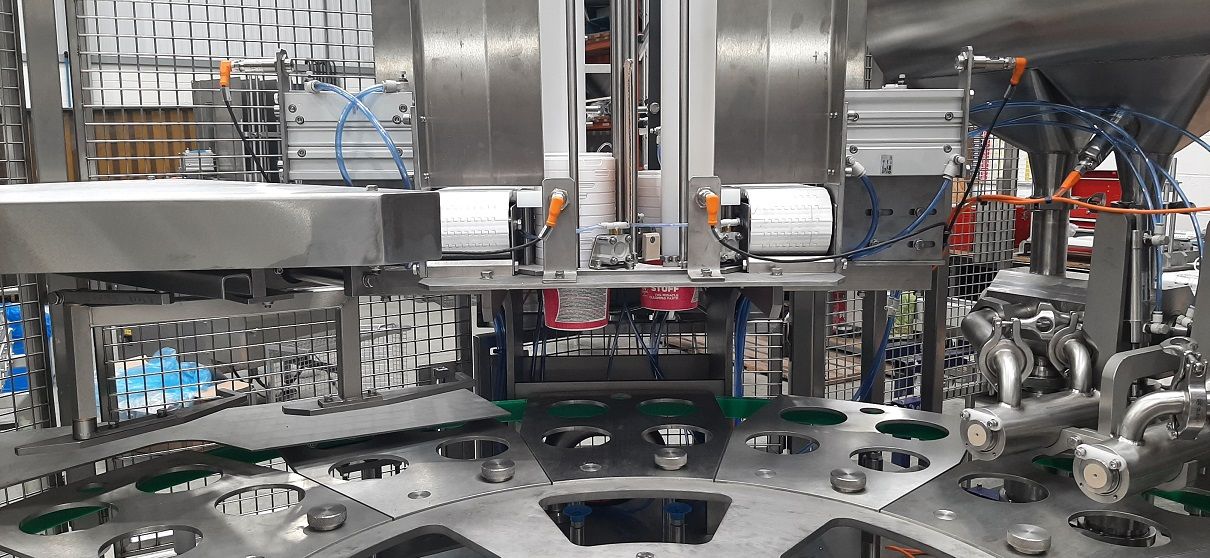

Rotary Pot Filling Machines: For lines where space, accessibility, and flexible format changes are important, Flexi-Pak's rotary pot fillers provide the same hygienic construction and reliable performance in a more compact footprint. Our designs allow for fast format changes to minimise downtime when switching between cup sizes or recipes, and the machines are also quick and easy to clean.

Linear (Inline) Pot Filling Machines: Built for high‑volume ice cream production, these systems deliver consistent, fast dosing into cups and tubs while maintaining tight tolerances for lids and seals. The linear (inline) format supports continuous operation and is scalable throughput, enabling ice cream manufacturers to meet seasonal demand without sacrificing accuracy or quality. Their servo-driven control helps manage repeatable fills even with chunky inclusions or ripple textures, ensuring uniformity across thousands of units per hour. Linear (Inline) machines can also be supplied as a dual-index and triple-index format to allow manufacturers to fit up to 3 different cup / tub sizes onto the machine at once, without the need for change part tooling removal. This system provides both speed and versatility.

Product Filling: Ice cream formulations often feature layers, sauces, or inclusions. Flexi‑Pak filling systems offer precise, programmable dosing for smooth, layered, or chunky components, with options for servo or pneumatically driven nozzle filling heads. Flexi-Pak filling systems are designed to seamlessly integrate with continuous feed ice cream freezers, to deliver a controlled and constant flow of ice cream to the filling nozzles. A bypass valve is also incorporated to divert product if production is halted for any reason.

End‑of‑Line Packing Systems: A complete packaging line requires seamless transitions between filling, sealing, and packing. Our end‑of‑line solutions include robotic or servo‑driven pick‑and‑place systems, case packing, and palletising options. These systems are designed for chilled or frozen environments, ensuring gentle product handling and reliable downstream throughput.

Ancillary Equipment: The efficiency of an ice cream line often relies on auxiliary components. We offer a wide range of stainless steel add‑ons—de-nesters, feed systems, conveyors, and integration kits—that optimise line flow and reduce changeover times. All ancillary items are designed for easy washdown and long service life, helping to keep downtime to a minimum.

Ice cream packaging environments demand equipment that is robust against cold, moisture, and sticky product residues. In all our designs, we make sure the machine is easy to wash. Stainless steel frameworks and food‑grade contact components support easy disassembly for routine maintenance, while modular controls and intuitive interfaces help operators run their lines with confidence and minimal training requirements.

Irrespective of whether we are working with a large retailer, contract manufacturers or artisan producers, our partnership approach will ensure that the final design is ideally suited to work efficiently with the specific product textures, fill volumes, and packaging formats.

If you're a commercial ice cream manufacturer planning to increase your capacity or modernise and need any help or advice, please don't hesitate to contact us – call 01427 612869 or email info@flexi-pak.co.uk