Helping Food Manufacturers Prepare For Growth: Now And In The Future

If you’re running a growing food manufacturing company, there will come a point where manual packing just can’t keep up, and automated end-of-line packing is not just a nice-to-have but becomes essential. When transitioning to an automated solution, it is vital that your new packing line be future-proof.

Future-proofing your move from manual to automated packing starts with clear thinking about your products, your growth plans and how easily your new line can adapt to change. Flexi-Pak’s **modular** machinery and end-to-end project support are designed specifically to help UK food producers scale without constant reinvestment.

Product and pack format

Before choosing any machinery, define exactly what you pack today and what you might pack tomorrow. This avoids buying a line that is “maxed out” on day one.

- Map your full product range: viscosities, particulates, fill temperatures, allergens, clean-label variants and seasonal SKUs.

- Make a list of your current and future pack formats: pots, trays, skillets, cartons, foils and lids, plus likely size changes as ranges expand.

- Consider branding and retail requirements: lid films, pre-cut foils, multi-compartment packs and shelf-ready outer cases.

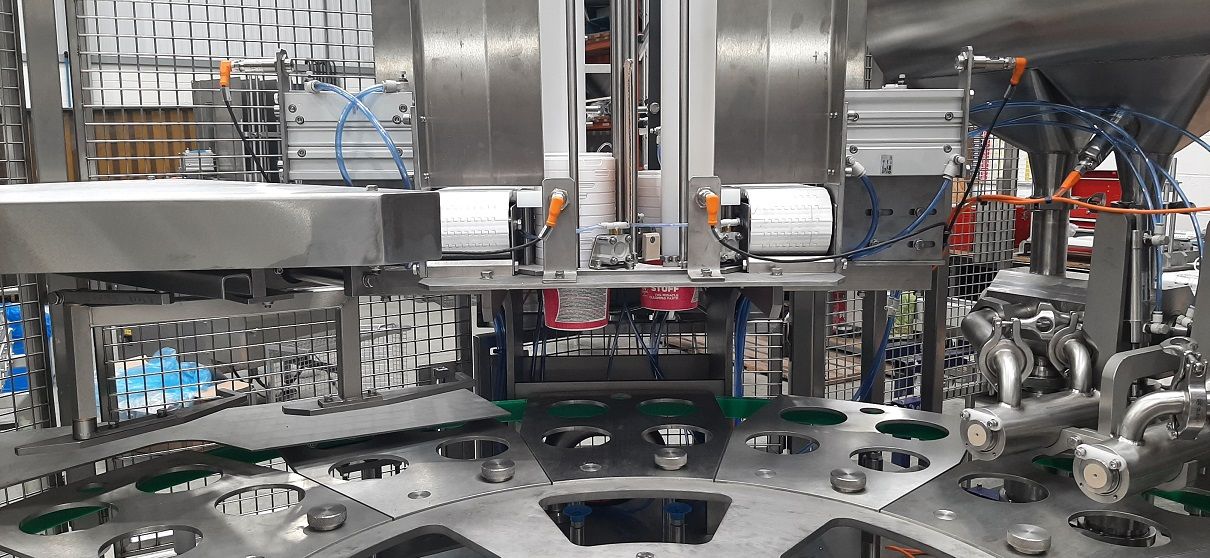

We supply a wide range of machines, including rotary and linear pot-filling, heat-sealing, and lidding machines, as well as pot, tray, skillet, and lid de-nesters. By offering a wide range of products and formats that can be integrated seamlessly into a line, our clients need only one supplier, saving them money and time at the point of installation and in the future as they expand or their line needs servicing.

Capacity and flexibility

A future-proof line should run efficiently at today’s volumes while maintaining headroom for tomorrow’s orders. Over-specifying slightly is usually cheaper than replacing equipment early.

- Define realistic throughput: target packs per minute for year one, then rework the line layout so critical machines can handle at least 30–50% extra.

- Prioritise rapid size changeovers and recipe recall so operators can switch between SKUs in minutes rather than hours.

- Choose modular systems that let you add stations later (extra fillers, additional lanes, new collators or case packers) without installing a whole new line.

Our rotary and linear fillers, product depositors and conveyors are designed for high flexibility, fast changeovers and instant recipe recall, making them suitable for short runs and frequent promotions.

Integrate end-of-line and automation

When moving from manual to automated packing, bottlenecks often simply shift downstream. A line is only as strong as its end-of-line systems.

- Look beyond filling and sealing to case packing, collation, labelling and palletising, ensuring each stage can match or exceed upstream speeds.

- Plan for retail-ready packaging: case orientation, tray counts, and mixed packs for club stores or foodservice.

- Consider robotics early: pick-and-place arms and servo-operated systems can de-skill repetitive tasks while improving presentation and consistency.

We’re experienced in developing end-of-line packing systems that feature robot arms or multi-axis servo arms to pick and place products into cases, boxes or trays, with optional case erectors, sealers and palletising as part of a turnkey solution.

Hygiene, compliance and uptime

Food producers cannot compromise on hygiene or regulatory compliance when automating. The right machine design makes cleaning and audits much easier over the life of the line.

- Specify full stainless steel construction and food-grade plastics, with easy access for cleaning and minimal dirt traps.

- Ensure guarding, interlocks, and control systems meet current standards while being ready for future retailer and British Retail Consortium (BRC) and Global Food Safety Initiative (GFSI) expectations.

- Plan maintenance from day one: ready access to spares, clear service intervals and remote support can dramatically reduce unplanned downtime.

Our machines are fully manufactured in stainless steel, built to strict hygiene standards and supplied with 12-month guarantees, with planned maintenance programmes, upgrades and comprehensive spares and engineer support available long term. And, as we’re based in the UK, we can be with you quickly if an emergency occurs.

A partner, not just a supplier

For many food manufacturers, the shift from manual to automated packing is as much about people and process as it is about machinery. A partner who understands line design, project management and lifecycle support can de-risk the transition.

- Look for in-house engineering, PLC programming and bespoke software skills so your line integrates cleanly with existing equipment and factory systems.

- Favour suppliers who offer turnkey project management: from 3D design and line layout through installation, commissioning, training and handover.

- Check their track record across sectors similar to yours, such as dairy, meat, ready meals, bakery, soups and convenience foods.

We offer bespoke design-and-build services, turnkey installations, line moves, machine upgrades and overhauls, backed by project management and on-site engineering support, giving food producers a single, accountable partner as volumes grow.

If you are reviewing your current manual packing operation and want to explore how an automated line could support your next stage of growth, and need any help or advice, please don't hesitate to contact us – call 01427 612869 or email info@flexi-pak.co.uk