Working With The Crème De La Crème: Helping Dairy Food Producers

Commercial dairy producers face intense pressure to keep products safe, fresh and attractively presented while controlling costs, managing labour shortages and meeting retailer and retailer audit standards.

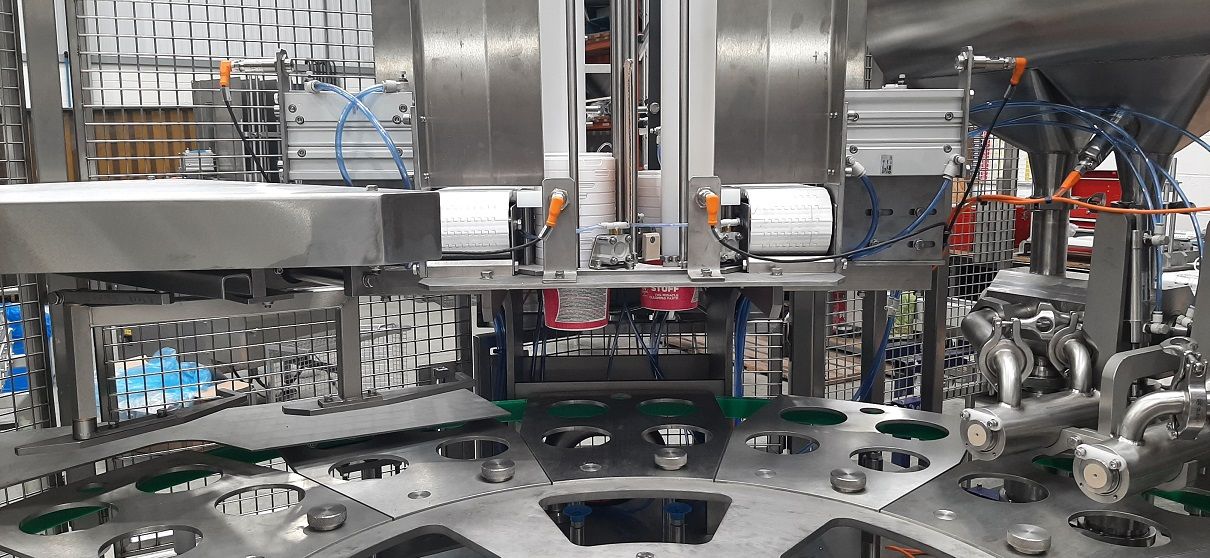

Our stainless-steel filling and lidding lines, de-nesting systems and ancillary automation are designed precisely to address these dairy challenges, from yoghurt and cream to dips, desserts and cheese portions.

Key packaging challenges faced by dairy food manufacturers

Dairy products are highly perishable, so even the slightest lapse in hygiene, sealing quality or temperature control can result in spoilage, waste and even product recalls. Retailers are looking for the longest shelf life possible, so their packaging machinery and the packaging format need to offer tight control over contamination, headspace and closure integrity.

At the same time, retailers want to see eye-catching pots, trays and multipacks, often in shorter runs, which puts a premium on fast changeovers and flexible machinery that can handle multiple pack sizes and recipes on a single line. Add to this the growing focus on sustainability and recyclable materials, and dairy businesses increasingly need equipment that can run different lidding films, pot formats and carton styles reliably and at speed.

Hygiene, compliance and line reliability

Auditable hygiene is non-negotiable in dairy, so the packaging equipment must be robust, easy to clean and designed to minimise product traps and harbourage points. Flexi-Pak's machines are entirely manufactured from stainless steel and food-grade plastics, helping dairy processors meet retailer and BRC/retail audit expectations while reducing clean-down time between product changeovers.

Downtime from older or poorly specified machinery can result in lost output, rework, leakages or damaged packs. Flexi-Pak offers in-house engineering design, PLC and software expertise, enabling upgrades, retrofits and line moves that keep dairy packing operations running efficiently as volumes and product ranges grow.

Flexi-Pak machines for dairy pots and trays

Flexi-Pak's core rotary and linear pot-filling machines are already widely used across the dairy sector for packing products such as yoghurts, desserts, soft cheeses, creams, and dips. These systems can be configured with bulk container loading, reel-feed lid assemblies and MAP gas flushing, giving producers the tools they need to extend shelf life while maintaining the clean, premium presentation retailers demand.

Linear pot filling machines, running at high cycle rates depending on configuration, are ideal for higher-volume dairy lines or multi-lane formats where throughput and repeatability are critical. Rotary pot fillers offer compact, flexible solutions for shorter runs, seasonal products, or NPD lines, while still benefiting from Flexi-Pak's robust construction, hygienic design, and recipe-driven changeovers.

Automation around the dairy line

Feeding and handling pots, trays, lids, and product are often bottlenecks on dairy lines, especially when labour is in short supply or when hygiene zoning restricts manual intervention. To overcome these issues, Flexi-Pak supplies de-nesters for buckets, pots, and trays, bulk lid loaders, vibratory product feeders, and elevator conveyors, which keep packaging materials and dairy products flowing smoothly into the fillers with minimal operator input.

Further downstream, Flexi-Pak's end-of-line packing systems and rotary accumulation tables help collate filled pots, present them for inspection and pack them into outer cases or onto pallets, improving overall equipment effectiveness and reducing manual handling. These elements can be supplied as part of a turnkey solution, ensuring mechanical and controls integration from de-nesting and filling right through to case packing.

Matching Flexi-Pak solutions to dairy needs

Different dairy products and formats place different demands on the packaging line, so selecting the right Flexi-Pak equipment mix is key to performance and return on investment. For single-serve yoghurt, desserts and dips in pots, the priority is high-speed filling, consistent lidding and impeccable hygiene, making Flexi-Pak's linear pot-filling machines, with options such as MAP gas flushing, reel-feed lidding and tailored hoppers, a natural fit.

Premium or short-run dairy lines, where frequent size changes and limited floor space are common, benefit from rotary pot filling machines that deliver rapid, often tool-less changeovers and recipe recall while maintaining production efficiency.

Family-size trays and buckets present different challenges in terms of container weight, ergonomics, and presentation, which Flexi-Pak addresses with pot, tray, and bucket de-nesters, bulk container and lid loaders, and complementary end-of-line packing systems to support reliable, repeatable handling.

For viscous or particulate products such as fruit yoghurts and inclusions, accurate dosing and clean product cuts are essential, so vibratory product feeders, appropriate product depositors and auger fillers can be integrated seamlessly with the pot fillers to maintain pack quality.

Where dairy sites are growing or modernising around legacy kit and tight layouts, Flexi-Pak's bespoke design and build capability, alongside machine upgrades, overhauls and turnkey line installations or moves, ensures that new and existing equipment work together as a coherent, future-ready packaging operation.

If you work in the dairy industry and are considering upgrading or installing a new filling and packing line and need any help or advice, please don't hesitate to contact us – call 01427 612869 or email info@flexi-pak.co.uk