Packing Instant Or Microwaveable Porridge

Over the last few months, we’ve seen a significant increase in enquiries from companies wanting to specify a new packing line for instant or microwaveable oat porridge, so what are the key factors to take into account?

At Flexi-Pak, we have over 15 years of experience in designing, manufacturing, installing and maintaining efficient and reliable packing lines. When it comes to packing porridge into tubs, most customers are looking for high throughput, product quality, and operational efficiency, with solutions tailored to the unique needs of oat-based foods.

Flexibility and Automation

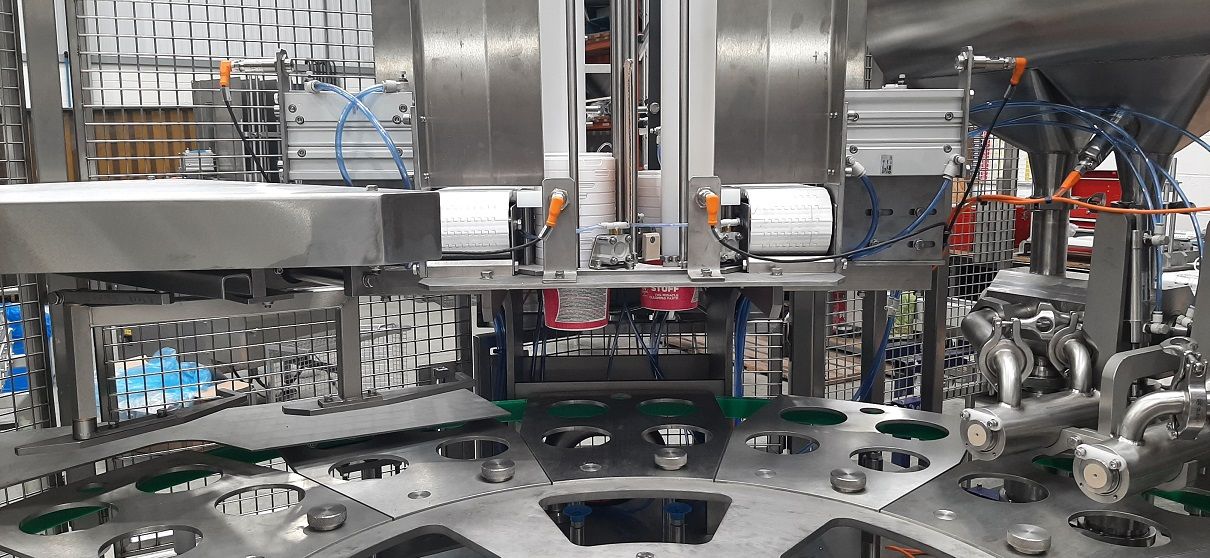

Choosing a flexible and automated packing line is vital for adapting to various tub sizes and recipes. Our modular rotary and linear pot-filling machines accommodate wet, dry, viscous, and powder products—essential for diverse porridge recipes. Features such as quick-release nozzles, multi-lane configurations (up to eight lanes), and recipe storage ensure quick and easy changeovers and programmable operations.

Throughput and Scalability

Our packing lines are designed to meet the desired production speeds, commonly ranging from single-lanes up to 50 pots per minute to multi-lane systems running up to 300 pots per minute. It is important to consider the line’s ability to scale up as demand increases, as well as other features such as automated bulk loading and fast, continuous motion drive mechanisms to help maximise efficiency while minimising downtime.

Hygiene and Food Safety

Instant oat porridge poses unique food safety challenges. Packing lines must be manufactured to high standards; that’s why we only use stainless steel and incorporate Clean-in-Place (CIP) systems. Integrated hopper agitators and probes also help maintain consistency and reduce ingredient loss.

Sealing, Preservation and MAP

To preserve freshness and extend shelf life, options like modified atmosphere packaging (MAP) and heat sealing are essential. Flexible reel feed assemblies and reliable conveyor systems enable secure tub sealing and smooth handoff to end-of-line systems.

Integration and Automation Downstream

Our packing lines do not operate in isolation; they’re part of longer lines, and so they must integrate seamlessly with end-of-line machines, such as robotic or servo-arm case packing, palletising, and automatic carton erecting.

Remote Support and Recipe Changeover

At Flexi-Pak, we believe that modern lines should incorporate remote diagnostic access, allowing engineers to receive early notification of required maintenance. Advances in functionality, such as remote diagnostics, are also seen in the HMI, where multiple recipes can be stored, allowing instant recall and minimal disruption during product changeovers.

Sustainability and Compliance

Sustainability is increasingly important - both for manufacturers and consumers. At Flexi-Pak we ensure that our designs accommodate sustainable practices, such as being able to work with both recyclable and compostable tub materials.

By considering flexibility, throughput, hygiene, automation, sealing performance, and sustainability, we can deliver a tailored packing lines that help food producers efficiently pack instant and microwaveable oat porridge into tubs.

If you’re considering upgrading or installing a new packing line to work with instant and microwaveable oat porridge and need any help or advice, please don’t hesitate to contact us – call 01427 612869 or email info@flexi-pak.co.uk