Lifting The Lid On How Flexi-Pak Helps Pie Makers Expand

Commercial pie makers scaling up production face multiple challenges when it comes to packing their products – thankfully, Flexi-Pak has a wealth of experience to draw upon in this sector.

From maintaining hygiene and product consistency to handling rapid changeovers and integrating increasing automation, growing pie producers have a lot on their plate. However, by working with Flexi-Pak and utilising the company's bespoke machinery solutions, pie producers with an eye on expansion don't have to worry.

Key Packing Issues for Scaling Pie Makers

Expanding pie production leads to higher volumes, a wider range of products, and stricter food safety standards. Major challenges include:

Efficient portioning and filling: Achieving uniform pie weights and fillings at speed, especially across diverse product lines.

Maintaining product integrity: Preventing pastry deformation and ensuring accurate placement, especially during high-speed operation.

Rapid changeover between products: For seasonal pies or SKU variety, downtime must be minimised, with tooling swaps and cleanouts fast and simple.

Traceability and recipe management: Scaling up requires robust controls for instant recipe recall and compliance with food regulations.

How Flexi-Pak Machines Address These Needs

Flexi-Pak offers a comprehensive range of packaging and pie-making machines, all designed and manufactured from its Gainsborough site.

Rotary and linear pot/pie filling machines: Engineered for precision portioning, these models automate the filling of pie shells, supporting wet and dry ingredients.

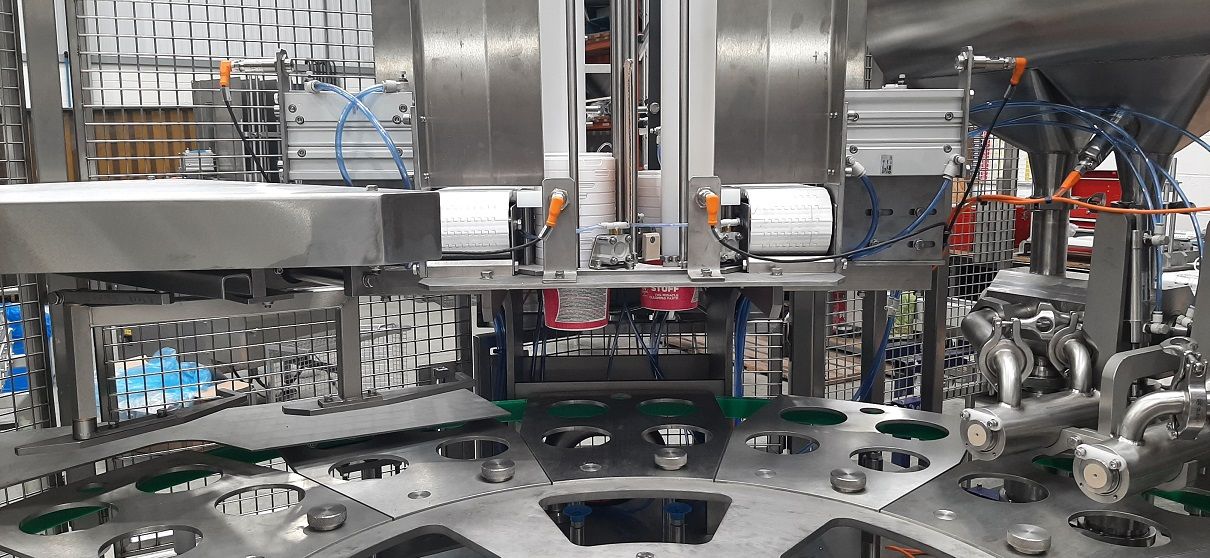

Automated pie-making lines (fully and semi-automatic): Mechanical systems are designed for consistent filling, crimping, and lidding, reducing manual effort and error in pie assembly.

Stainless steel construction with food-grade plastics: Enables easy cleaning and strict hygiene compliance while withstanding intensive production cycles.

PLC-controlled automation: Custom software provides instant recipe recall, production parameter programming, and rapid size changes for various pie formats.

Denesters and depositors: Mechanically sort and feed pie containers, foils, or pre-cut lids, handling varying sizes and packing styles to prevent jams or cross-contamination.

Technical and Mechanical Advantages

As you would expect from a leading manufacturer that has worked with some of the largest pie makers in Britain, Flexi-Pak's machines offer several technical and mechanical advantages compared to the competition.

Rapid changeover capability: Flexi-Pak's machines feature modular change-part tooling, allowing operators to quickly shift between pie sizes or recipes, essential for batch production.

Integrated conveyor systems: These transfer pies efficiently between stations—whether filling, lidding, or final packing—while preserving alignment and reducing product handling damage.

High flexibility: Suitable for pies with different fillings, sizes, and even crust types, Flexi-Pak solutions can be programmed and reconfigured as production demands change.

Custom design and upgrades: Flexi-Pak engineering services provide retrofits and bespoke adaptations for new recipes, tray formats, or compliance upgrades to support expanding pie businesses.

More Than Machines

While there is no doubt that Flexi-Pak's machines are built to exacting standards and deliver exceptional reliability and efficiency, there are additional factors to consider when deciding which company to partner with when installing a new pie packing line or improving the performance of an existing one.

Turnkey project management: Can the company you're considering undertake complete line installations, including planning, machine design, and commissioning, minimise scaling headaches. Flexi-Pak is proven in this area, having undertaken several end-to-end projects for pie makers.

Engineering maintenance and cover: Can the company you're considering provide ongoing support, similar to Flexi-Pak's team, which offers ongoing machine servicing to ensure maximum uptime and reliability?

Spare and consumable parts: Finally, if you need a spare part, then you want it quickly. By maintaining a large in-house stock of parts, Flexi-Pak keeps downtime to a minimum. Flexi-Pak always has stock available.

If you're a commercial pie maker planning to increase your capacity or modernise and need any help or advice, please don't hesitate to contact us – call 01427 612869 or email info@flexi-pak.co.uk