Soup Production And Packing: Overcoming The Challenges

Companies that manufacture soup in large volumes face significant challenges which need specialist expertise to overcome.

Whether the company is manufacturing and supplying soup to supermarkets or scaling up from kitchen or small-scale production, the obstacles are the same: liquid handling, hygiene, packaging integrity, line flexibility, and automation. Flexi-Pak offers engineered solutions and support that address each of these issues.

Liquid and Viscous Product Handling

Soup lines must manage liquids with varying viscosities, particulate mixes (such as chunks, pasta, and grains), and hot-fill requirements. It is crucial that the packing machinery deployed maintains highly accurate portioning, ensuring that fill levels are precise and that splashing or product waste is minimised, especially at high speeds.

Hygiene and Cleaning Standards

Soup production must be conducted in a high-care environment to prevent contamination. The packing machinery, conveyors and other elements of the packing line, whether small or large, need to be constructed from easy-to-clean materials such as stainless steel and food-safe plastics. Clean-in-place (CIP) options and tool-free access are also desirable, and sometimes essential for audit purposes, as they reduce cleaning downtime and support regulatory compliance.

Packaging Integrity and Leaks

Seal quality and package design are crucial; failures cause leakage, spoilage, and costly product recalls. When designing a packing solution, the manufacturer must consider key factors such as compatible films and containers, calibrated sealing parameters, and effective moisture barriers. It is also essential to consider the strength and integrity of seals and containers, as weak seals or distorted containers can result in high wastage rates.

Production Flexibility and Changeover

Consumers want choice, and supermarkets, in particular, want to offer a broad range of products. This means that soup manufacturers are producing several different recipes in close succession. The challenge, therefore, is how to changeover quickly – not just the recipe, but also the portion sizes, packaging format, and container type. Minimising downtime and maintaining throughput is essential. It is also a significant challenge. The packing machinery deployed, therefore, needs to be easy to clean and adjust, and offer rapid recipe recall and instant resetting.

Automation and End-of-Line Integration

In most situations, manual labour involved in mass production leads to a bottleneck. Packing and labelling are two examples of where this can occur. Moving away from manual labour to an automated process can increase throughput, ensure uniformity and lower overheads.

How Flexi-Pak Helps Engineering Managers and Directors

Bespoke Machine Design

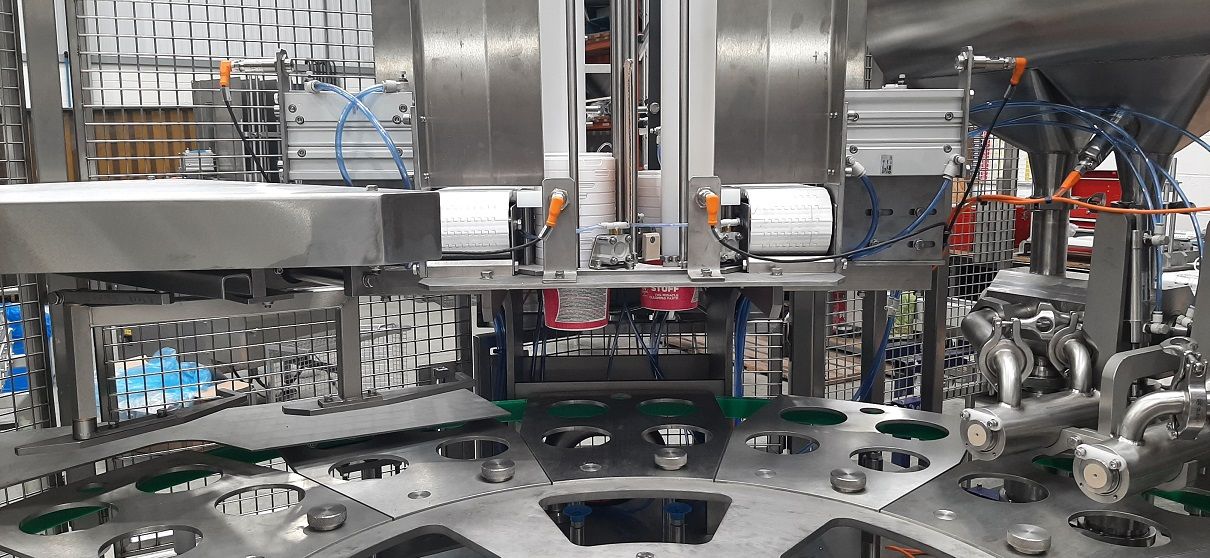

Flexi-Pak are experienced in designing and manufacturing efficient and reliable rotary and linear pot filling machines, product depositors and conveyors tailored to exact production and container specifications. Custom systems can handle wet, chunky, or creamy soups with variable fill.

Hygiene, Cleaning and Compliance

When it comes to soup production, Flexi-Pak only uses stainless steel and food-grade plastics in its machinery, as this offers both easy cleaning and compliance. The company's machines feature tool-free access and optional CIP systems to minimise disruption and meet regulatory requirements.

Seal Quality and Packaging Reliability

Flexi-Pak supports optimised sealing parameters (temperature, pressure, dwell time) and robust compatibility between films, foils, and pre-formed containers, reducing leakage and distortion. The company's experienced engineers can assist with tooling calibration and design trials to match product needs.

Fast Changeovers and Flexibility

Flexi-Pak designs its machines and production lines to allow quick and easy size and recipe changeovers, instant PLC recipe recall, and easy adjustment for different formats. This flexibility suits soup operations with frequent changes and diverse product lines.

Turnkey Project Management and Aftercare

Flexi-Pak provides more than just single machines; the company can undertake end-to-end project management, from design and installation through maintenance and upgrades, including end-of-line packing systems (robotic case packing, tray loading, palletising, and integration with existing lines). Technical support, training, and maintenance contracts are also available to keep lines running smoothly and efficiently, thereby reducing unplanned downtime.

Flexi-Pak's flexible engineering, focus on hygiene and reliability, rapid changeover capability, and complete support services address the main pain points faced by soup manufacturers.

Custom packaging solutions, end-of-line automation, and a commitment to ongoing support make Flexi-Pak a partner of choice for engineering managers and company directors seeking performance, compliance and adaptability in modern soup packing operations.

If you're considering upgrading or installing a new filling and packing line to work with soup or a similar liquid and need any help or advice, please don't hesitate to contact us – call 01427 612869 or email info@flexi-pak.co.uk